Reciprocating Friction Tester convenience store|high frequency friction tester : export A ball-on-plate reciprocating friction and wear test system, assessing the performance of both fuels and lubricants under boundary conditions. The HFRR is a ball-on-plate instrument used . Resultado da 29 de jul. de 2022 · Akiko Is A Well-Known UK Musician . Akiko Matsuura was born in Osaka, Japan in 1994. The daughter of hardworking parents who owned a restaurant, the young girl was often left to her own devices. After watching a series about a female drummer who was in a boy band, Akiko .

{plog:ftitle_list}

webOuça Sentada Inesquecível no Spotify. MC Vick Moranguinho · Música · 2.022.

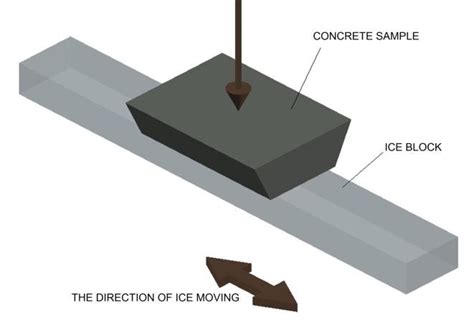

slip friction test

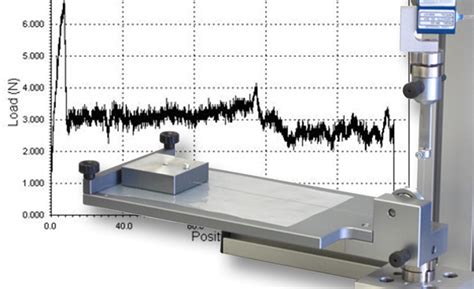

Evaluate fuel lubricity, predict the performance of additives, and study friction wear with our HFRR high frequency reciprocating rig. This next generation Rtec Instruments HFRR testing machine contains programmable force control (no .Using various sensors it measures friction, wear, and adhesion of any reciprocating test setup with ease. The patented in-line 3D profilometer automatically measures topography change during the test.A ball-on-plate reciprocating friction and wear test system, assessing the performance of both fuels and lubricants under boundary conditions. The HFRR is a ball-on-plate instrument used . A reciprocating sliding friction and wear test rig is a device used to study materials’ wear and friction properties under sliding conditions. It simulates the conditions of real-world applications such as gears, bearings, .

The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the . The aim of this work is thus to develop a novel reciprocating tribometer and test method that enables friction and wear tests under low-speed reciprocatory sliding with contact pressures up to 90 MPa in a flat-on-flat .

windows 10 memory hard drive test

Using various sensors it measures friction, wear, and adhesion of any reciprocating test setup with ease. The patented in-line 3D profilometer automatically measures topography change during the test. The module .The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance of fuels and lubricants. It is particularly suitable for wear testing relatively poor lubricants such as diesel fuels and for boundary friction measurements of . The variation of friction force between upper test specimen and nether test specimen is very complicated on the reciprocating wear tester. There are many factors exerting influence on it. Based on the bench test, a system is developed for measuring the variation of the friction force between upper and nether test-piece.Oil box design: Oil box design adopts 2ml marked line, convenience to add the oil. 4. Steel ball chuck: Steel ball chuck is convenience to dismantle . 2.Set the test parameter: Stroke length, reciprocating frequency, friction, test temperature and test time. It also can do the course setting to each parameter. 3.Control the mechanical part .

These pits can store more lubricating oil and improve friction performance under starved lubrication conditions [31]. Another important role of graphite is to improve the thermal conductivity of cast iron. Usually, friction heat can reduce the material's hardness and thermal fatigue properties, thus affecting the transition of the wear state . The variation of friction force between upper test specimen and nether test specimen is very complicated on the reciprocating wear tester. There are many factors exerting influence on it.

Ball-on-flat test: The ball-on-flat test is a method used to evaluate the wear characteristics and frictional properties of materials under controlled conditions. This test typically involves a spherical specimen (the ball) making contact with a flat surface, allowing for the study of tribological interactions, including wear mechanisms and friction coefficients.Koehler’sK93405 tests diesel’slubricity by High-Frequency Reciprocating Rig (HFRR) technology. HFRR is a reciprocating friction and wear test system which is going under microprocessor control. It provides a fast and repeatable assessment of the performance of fuels and has become an industry-standard test for diesel fuel lubricity. The vertical load, friction ball diameter and reciprocating movement frequency (friction speed) are selected as the experiment factors. The cutting tools was installed in the special designed fixture on a reciprocating movement wear test machine. The wear depth increases with the increase in the Z-load, ball diameter and frequency.contact. Test loads and speeds are to be determined by the severity of the proposed application or purpose of the testing. Either of two sets of testing conditions (designated Procedures A and B) may be used. 6. Apparatus 6.1 General Description—Fig. 1 shows the arrangement for the reciprocating ball-on-flat wear test available on a commer .

conditions: (a) the principle of sliding friction and the wear tester; (b) the principle of a wet abrasive wear tester; ( c ) the principle of a wear tester that can simulate complex working .

Friction and wear study of sliding surfaces plays a prominent role in the development of materials for various applications. The development of a low-cost multipurpose reciprocating tribometer at constant sliding speed to study the tribological properties of a material under dry, wet and high temperature conditions is presented in this paper. The tribometer has the ability of .

It enables stable reciprocating friction testing. This device strokes up to 40 mm and is designed to be driven by the high speed vibrator for frequencies above 30 Hz. Data acquisition of RFW160 system uses National . Data acquisition systems normally store data at above 100 The test rig can evaluate the performance of different surface treatments such as hardening, nitriding, and electroplating.This can provide valuable information on how different surface treatments can be used to . The friction and wear properties of PTFE and graphite-MoS2 filled PTFE composites were studied by using a reciprocating friction and wear tester under the different load, speed and wear time, and .

sliding friction test

The more usual arrangement is Fig 1 The simple reciprocating friction and wear tester 0301-679X/80/010011"05 .00 1980 IPC Business Press TRIBOLOGY international February 1980 11 Moore and Noah - Friction and wear tester pneumatic loading of the test sample, as shown in Fig 3. Here, a pneumatic load cylinder under the action of air pressure .2. Set the test parameter: Stroke length, reciprocating frequency, friction, test temperature and test time. It also can do the course setting to each parameter. 3. Control the mechanical part running time, it can keep monitoring the stroke length, reciprocating frequency and .

Aiming at the friction and wear experiment requirements for different solid materials under different conditions, a new reciprocating friction and wear tester is proposed. When it comes to power and convenience, the KIMO Reciprocating Saw doesn’t compromise both. This versatile cordless reciprocating saw makes demolition super-easy. Performance . It can reach a speed of up to 3000SPM with a stroke length of ¾ inch, giving users enough cutting power to get through most materials.Polymer Testing 9 (1990) 195-211 Reciprocating Sliding Friction and Wear Test Apparatus S. M. H. Benabdallah Department of Mechanical Engineering, Ecole Polytechnique de Montrral, PO Box 6079, Station 'A', Montreal, Quebec, Canada, H3C 3A7 (Received 4 November 1989; accepted 2 December 1989) ABSTRACT As the friction and wear properties of polymers are .Download scientific diagram | Reciprocating friction tester. from publication: Evaluation of lubrication properties of hydrogel artificial cartilage materials for joint prosthesis | Poly (vinyl .

To demonstrate its flexibility and the degree of ease for modification, we explored several open-source solutional options for various friction contact modes or environments (as shown in Fig. 10), e.g., ring-block type tribometer (Fig. 10 (a)), reciprocating type tribometer (Fig. 10 (b)), corrosion-friction type tribometer (Fig. 10 (c)), and .Historical/Traditional Test Geometry. The classic work of Thurston 1, Martens 2, Stribeck 3 and Hersey 4 were done using a journal-bearing geometry, which possesses all of the above requirements (Figure 3). An instrumented journal-bearing test allows for evaluation of the friction over a range of relative velocities and/or loads.

In the pin-dish sliding wear test, at room temperature, under 20 N test, the friction coefficient of the sample with rough lamination/smooth lamination/resin carbon is 0.13 and the mass wear loss .

The aim of the present work was to investigate the reciprocating friction and wear behavior of MCMBs-derived reaction-formed SiC submitted to dry sliding tests against bearing steel ball under different loads, in order to determine the effects that the microstructural features and properties can have on friction and wear behavior, as well as to .To facilitate the in-depth study of the tribological behavior of texture friction pairs in the process of reciprocating friction. The micro-displacement deformation output model of compliant mechanism is deduced using a new method for indirectly measuring friction coefficient through micro-deformation of double parallel four-bar compliant mechanism. Then, the whole structure .

linear wear friction testing

linear friction tribometer test

Resultado da Watch Deadloch — Season 1 with a subscription on Amazon Prime Video. An irreverent twist on the crime procedural, Deadloch 's addictive mixture of mystery and mordant .

Reciprocating Friction Tester convenience store|high frequency friction tester